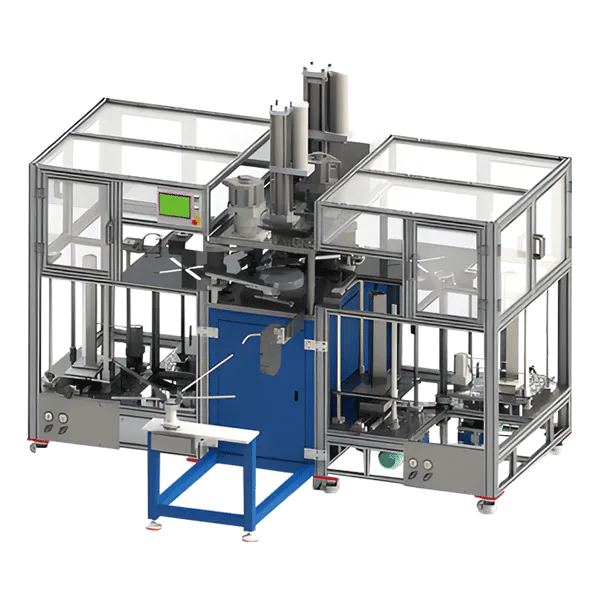

The fully automatic winding machine utilizes advanced winding mechanics with synchronized tension control to ensure uniform layering of metal strips and fillers like graphite/PTFE. Automated servo-driven rollers and precision U-channel forming guarantee consistent density and profile accuracy for leak-proof seals.

The fully automatic winding machine features PLC-programmed operations and robotic arms to achieve rapid cycle times. Dual-loading systems for rings and fillers enable continuous production, while quick-change molds minimize downtime during size switches.

Key components like laser marking and performance test modules ensure traceability and compliance. Hydraulic pressure up to 5 tons and air-oil assembly systems deliver flawless guide ring deformation, while IoT-ready controls support real-time adjustments for high-volume output.

Fully Automatic Gasket Machines streamline the production of high-performance spiral wound gaskets by combining precise mechanical winding with advanced automation—our gasket machine for sale delivers this fully automated workflow as a turnkey solution.

At the core of the process, metal strips (typically stainless steel or carbon steel) and filler materials (graphite, PTFE, or mica) are fed into a synchronized forming system where they are coiled into a continuous spiral. The metal strip passes through precision U-channel rollers for structural integrity while the filler provides a compressible sealing layer.

The machines incorporate robotic arms for guide ring assembly, hydraulic presses (up to 5 tons) for inner/outer ring shaping, and PLC-controlled laser marking for traceability.